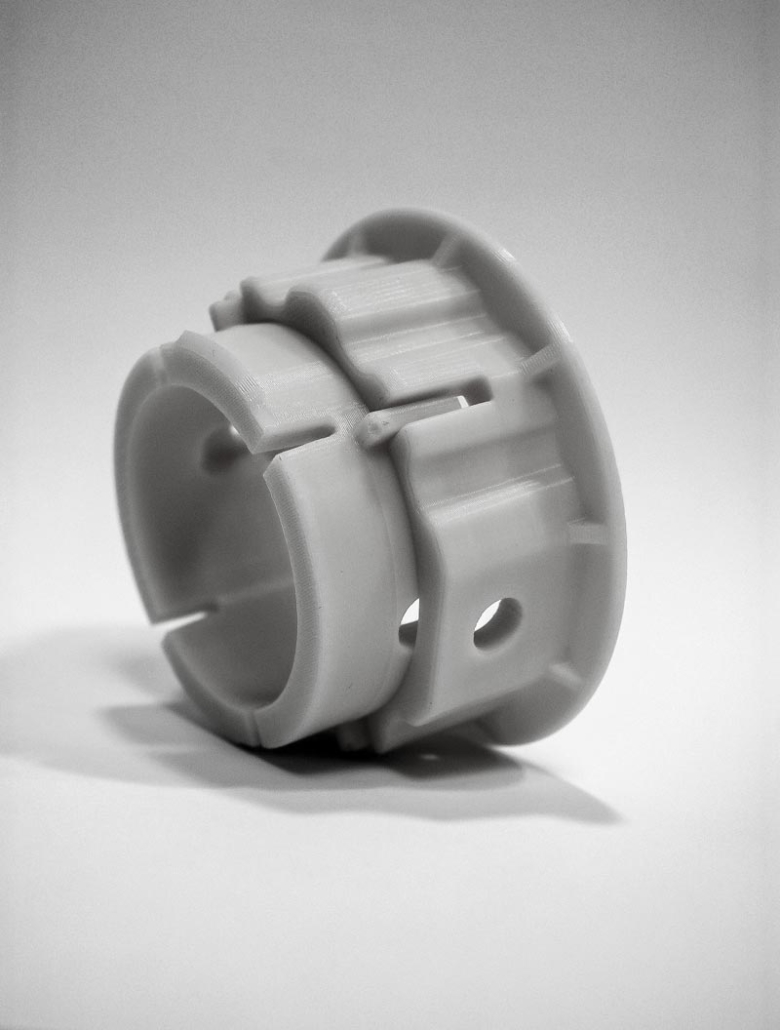

3D printing has earned an important role in the medical sector, enlarging the possibilities of providing personalized assistance, producing customized medical products, and pre-surgical models.

According to a report by the market research institute, SmarTech, the market of medical 3D printing, materials, services, software and hardware included, is estimated to be at $1.25 milliard. Within 2027 this number should grow up to $6.08 milliards.

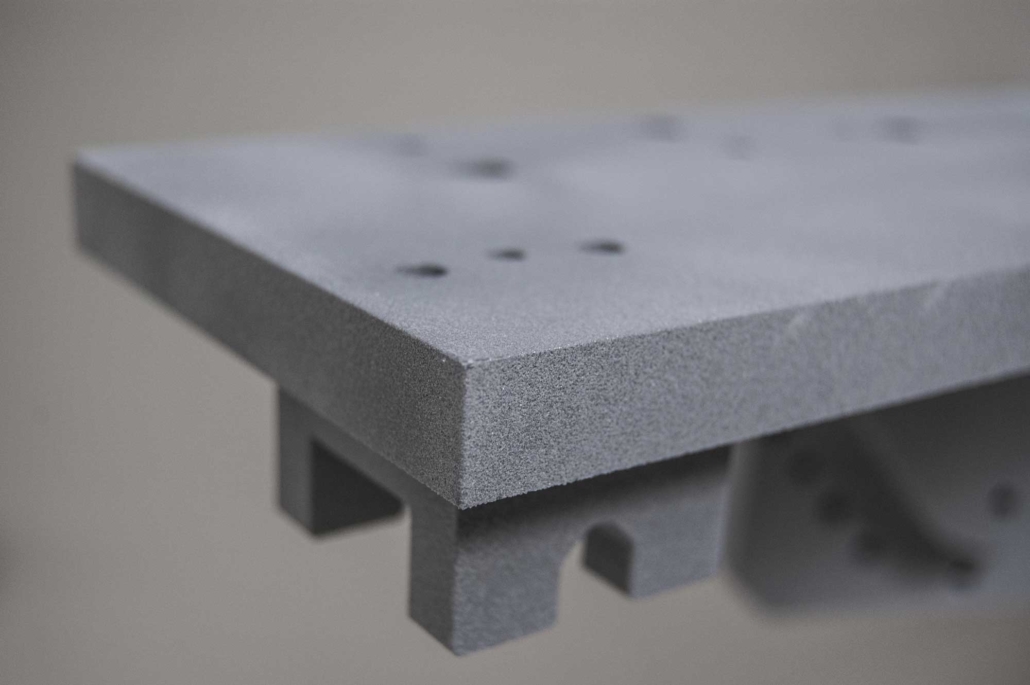

The three principal areas will be the orthopaedic field, personalized surgery and medical aids. The orthopaedic field is one of the greatest growth opportunities of the technology. SmarTech foresees that by 2021 over 1 milliard implants will be printed in 3D metal.

A key factor of this growth is the ability to use 3D printing for creating orthopaedic implants of superior quality. These implants have complex mesh structure, which allows a better bone growth and, in the end, better treatment results.

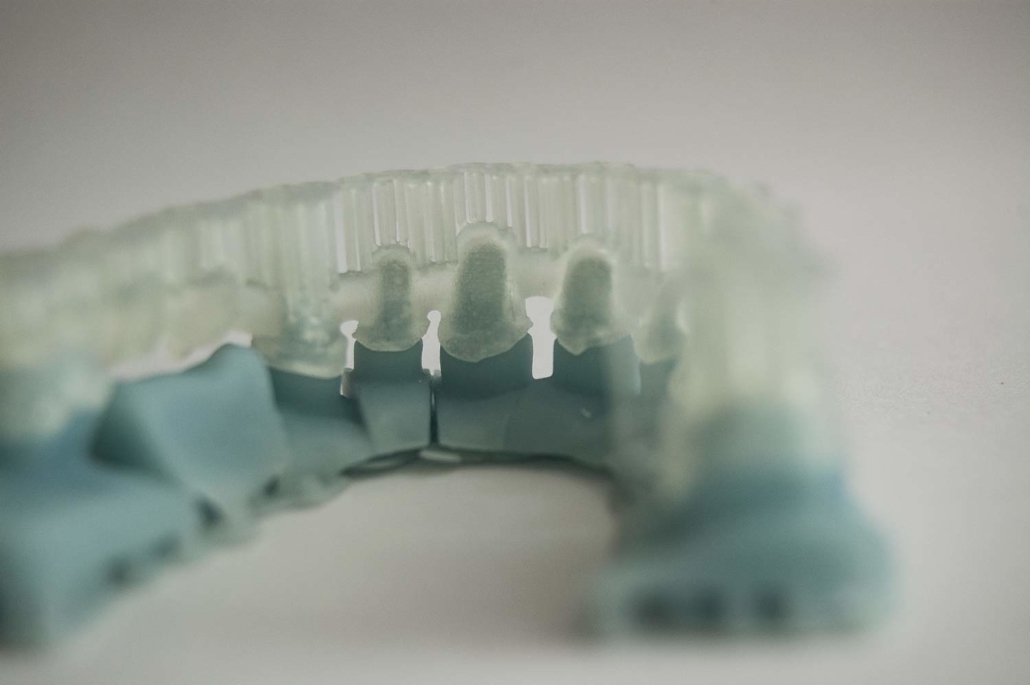

In the dental field, 3D printing is well positioned to become the principal digital process for the production of dental models, orthodontic aligners, restorations and other activities.

Orthodontic transparent aligners are a market that is ready to prosper with 3D printing. For example, Align Technology, the producer of transparent aligners Invisalign, has recently increased its investment in the 3D printing technology (SLA, 3D Systems). At Align, technology is used to produce moulds for over 320.000 unique transparent aligners per day.