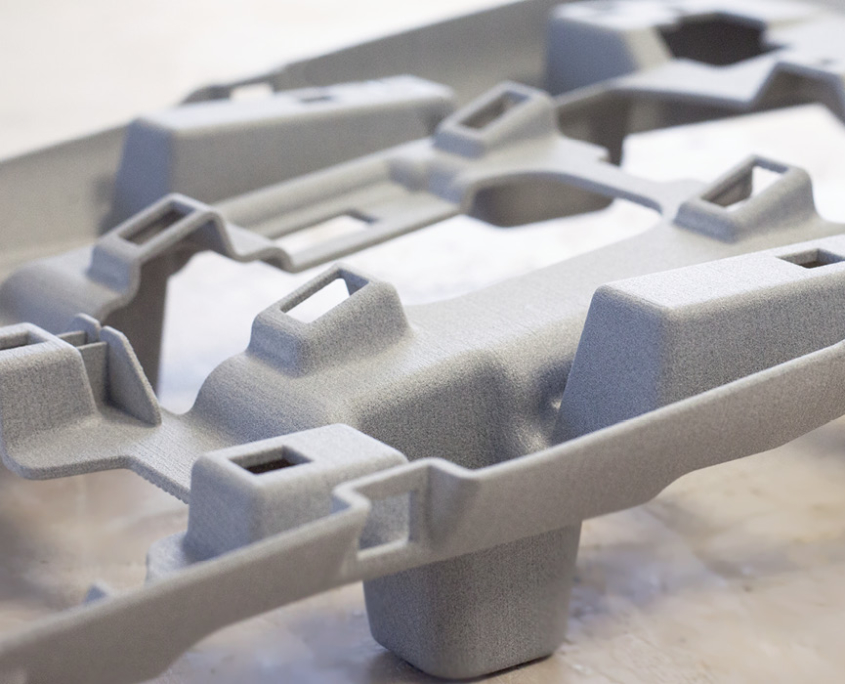

Alumide

General characteristics

Alumide, of silver grey colour, is a polyamide powder filled with aluminium. This material is characterized by its high rigidity, metallic look and good post-processing possibilities.

Finish

The surface finish of the Alumide products can be refined by stamping, polishing or coating. The advantage of this material is the possibility to carry out non-aggressive finishings with a reduced wear by material removal processes such as milling, drilling or lathing.

Applications

Alumide is mainly used in the automotive sector to realize rigid parts with a metallic look and tool parts, to inject and mould small productions or simply create illustrative or expositive models having a metallic look.

Carbonmide

General characteristics

CarbonMide is PA12 black powder filled with carbon fibre. It stands out for its excellent rigidity and a maximized weight – resistance ratio. A fundamental characteristic is its lightness that makes it perfect to design resistant, extremely rigid yet light objects.

Finish

The Carbonmide surfaces have a rough finish, that can be sanded but not polished. The black colour derives from the powder reinforced with carbon fibres that render the piece black all over its volume.

Applications

Typical applications of Carbonmide are manufacts exposed to strong mechanical stress such as: prototypes, gearing systems, articulated objects but also medical or electronic elements. It is a highly requested material for aerodynamic components in motorist sports.

Metal

General characteristics

Metal powder casting is an advanced process of additive production allowing the creation of metal parts with a complex design directly from models realized in CAD 3D. For this printing technology you can chose various types of metals.

Finish

The surface finish of metal product can be refined by tumbling, sanding and coating.

Applications

This technology is used in various automotive and aero-space sectors but also in research, scientific analysis and biomedical applications.

Polyamide

General characteristics

Polyamide forms a polymer class generally known as Nylon. It is a bio-compatible material according to the norm EN ISO 10993-1 and USP / Level VI / 121 °C and approved for food contact in compliance with the EU 2002/72 /EC Plastic Directive.

Printing with this material allows a high detail resolution and a high selectivity. It is characterized by a good resistance to chemical agents, a low friction coefficient and a good resistance to abrasion.

A typical characteristic of parts synthesized in PA is the perfect harmony between mechanical solidity and elasticity on a wide temperature range that make this material adequate for parts with different geometries, dimensions and requirements.

Finish

Polyamide based laser synthesized parts can be finished in various ways such as metallization, fire coating, vibration grinding, tank dying, gluing or powder coating.

Applications

Typical applications for this material are functional parts with design quality, exposed to high thermic or mechanical stress. It is often used to replace typical plastics used in injection moulding, to realize prototypes and spare parts. The biocompatibility permits to realize prosthetics and can be used to create joining elements for mobile parts because of its resistance to abrasion.

Glass filled polyamide

General characteristics

The glass filled polyamide belongs to the polymers commonly called Nylon. Parts realized with this material stand out for their excellent mechanical properties, for their very smooth surfaces and a high precision degree, accuracy and dimensional details.

Finish

To manufacts made of glass filled polyamide can be applied different surface finishes that improve their appearance and mechanical resistance.

Applications

Typical applications of glass filled polyamide are in the automotive sector, especially parts in the engine bay. This material is ideal also for drawing dies or for any other application requiring a low abrasion wear and a high deformation temperature.

Resin

Series PRECISA: Precision, High Definition and Details

The material Precisa is used to realize models with extra-smooth and detailed surfaces, requiring high resolution and accuracy. It is ideal in the dental sector whose models require extreme precision; it is perfect also for modelling, a sector where also the smallest details are fundamental and for the jewellery that requires an accurate precision in detail creation.

Series INVICTA: Invincible and resistant

The Invicta series has been specifically developed for the production of functional prototypes, concept-design, snap-fit parts requiring accuracy, precision and resistance. The materials of this series keep their physical and mechanical characteristics over the time.

Series FUSIA: castable and right for all applications.

The series Fusia has been specifically developed for lost wax micro-casting of jewellery models, fashion accessories, castable pieces for the industrial sector and ash-free for the dental sector. It is designed for building modelling and detailed parts requiring the highest possible resolution.

GL4000 and DS3000

Materials for surgical guides and gingiva-like parts

DS3000 is a biocompatible transparent material of Class I used to realize surgical guides requiring high precision and accuracy. GL4000 is a gingiva-like material used to create models with soft tissues.

Series THERMA: high definition at high temperatures

Nanoceramic materials belong to this series and are developed for the creation of gum moulds, vulcanized masters and models for thermo-forming. These high definition materials are suitable to realize models with extra smooth and high-temperature resistant surfaces.

Primepart St PEBA

General characteristics

Our rubber-like material is produced by synthesizing PrimePart® ST (PEBA 2301), an elastomer that has been developed and optimized for a synthesizing laser system. This material is ideal to realize functional, flexible high-quality components. It is important to highlight that this material, independently from its geometric structure, can be designed in various thicknesses and has the specific ability to react in different ways to various mechanical stresses.